Regulating Tools

Recognizing that piano regulating tools are generally uncomfortable and unwieldy to use, Wessell, Nickel & Gross has developed its own line of tools specifically designed to provide superior comfort and enhanced utility.

The problem with most of the regulating tools on the market is that they were designed for the most common type of piano 25 years ago—upright pianos. Today, the market has changed to the point where about half of the pianos that are sold are grand pianos, however, most regulation tools are still designed for upright pianos.

Two problems too many.

There are usually two fundamental flaws with traditional regulating tools when bench regulating a grand piano—the tools are too long, and their combination handle makes them cumbersome.

These tools are made to be long enough to reach down and into upright actions. This makes them too long to be efficient for regulating grand pianos. A tool that is too long is unwieldy and hard to control, which makes its user exert unnecessary and excessive effort to accomplish his task.

The other problem with traditional tools is that they are designed to be used with a combination handle. While combination handles are great for in-house technicians, they do not perform very well for bench regulating grand pianos—its “one size fits all” approach makes the tools awkward to handle, as well as adding to the excessive length problem.

Not too long, not too short—just right.

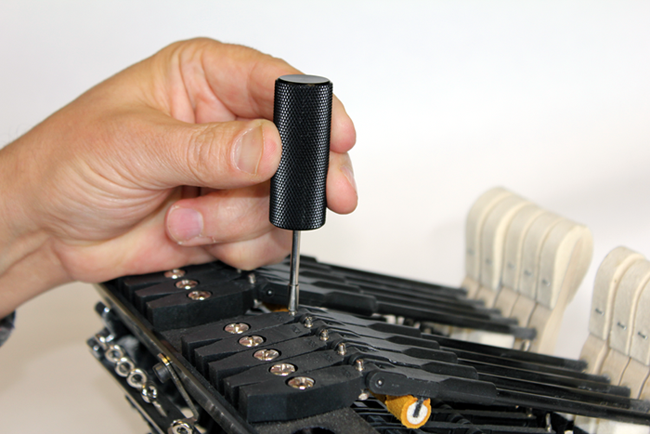

Wessell, Nickel & Gross regulating tools are designed to be the appropriate length for the appropriate task. For instance, to adjust a drop screw on a grand piano your screwdriver doesn’t need to be over a foot long. In fact, not counting the handle, WNG’s drop screwdriver is only about two inches, which allows you to rest your hand on the rail. This provides the technician with more comfort, less fatigue, and a faster regulation.

Sometimes bigger is better.

Wessell, Nickel & Gross designed its regulating tool handles’ diameter to be relatively large so that technicians can hold them with three fingers. This creates more leverage and gives more power to the piano technician’s hands, making regulating much easier.

Improved handling.

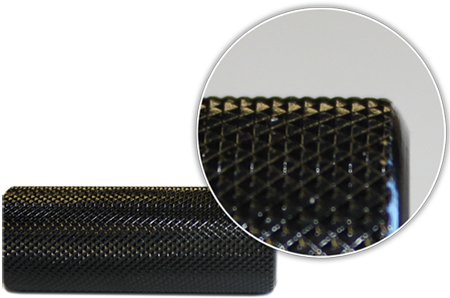

Wessell, Nickel & Gross’ tool handles are cylinders made from knurled aluminum that are hard-anodized black. This provides both a slip-free grip that makes precise regulating easier, and a stunning black finish that is highly resistant to scratching or chipping—one that will last for many years to come.

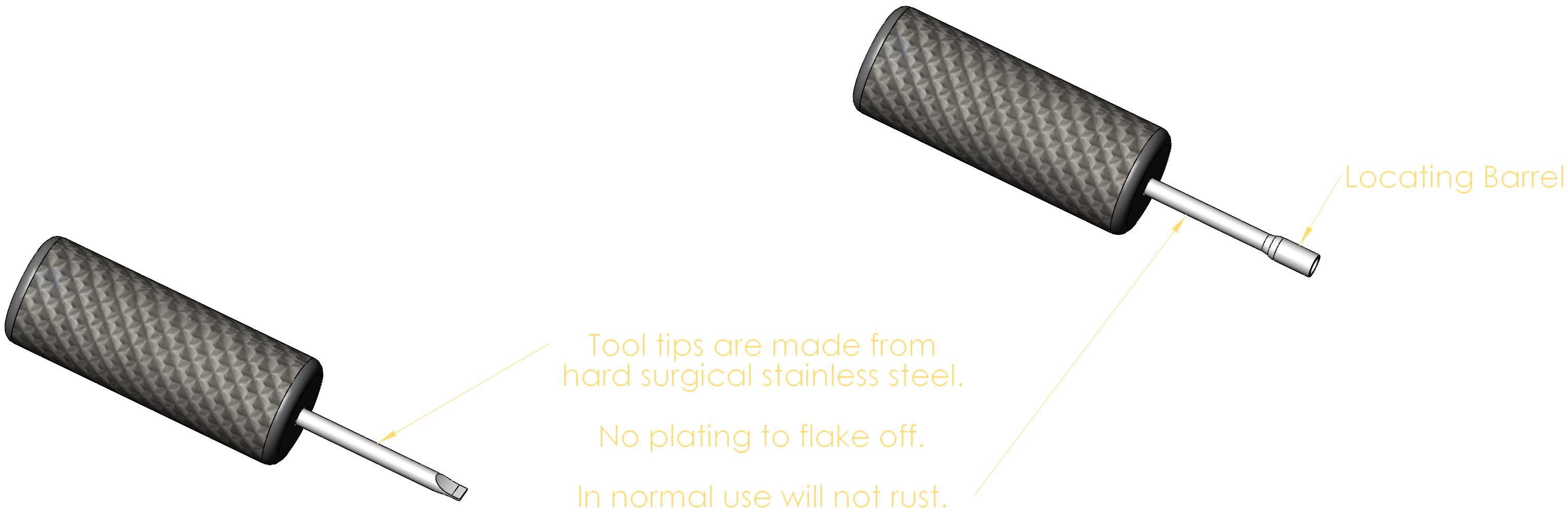

Performing surgery. On a piano.

If piano technicians have the ability to restore, revitalize, and rejuvenate a piano, why not provide them with equipment that even a heart surgeon would be proud of? Wessell, Nickel & Gross’ regulation tools are made from polished Surgery-Grade 420 Stainless Steel which is highly resistant to rust and does not have any plating, which is very prone to flaking off. The result is a tool that is not only incredibly durable and can stand the test of time, but it can look good doing it too.

Regulating Tool Kit

Drop Screwdriver

Unlike most drop screwdrivers, WNG's are intentionally made to be very short. This allows the technician to easily steady his hand on the shank flanges while regulating. WNG also offers two different versions of its Drop Screwdriver--one with a barrel and one without. The barrel helps to locate the tool on the drop screw, however, some technicians prefer not to have this barrel.

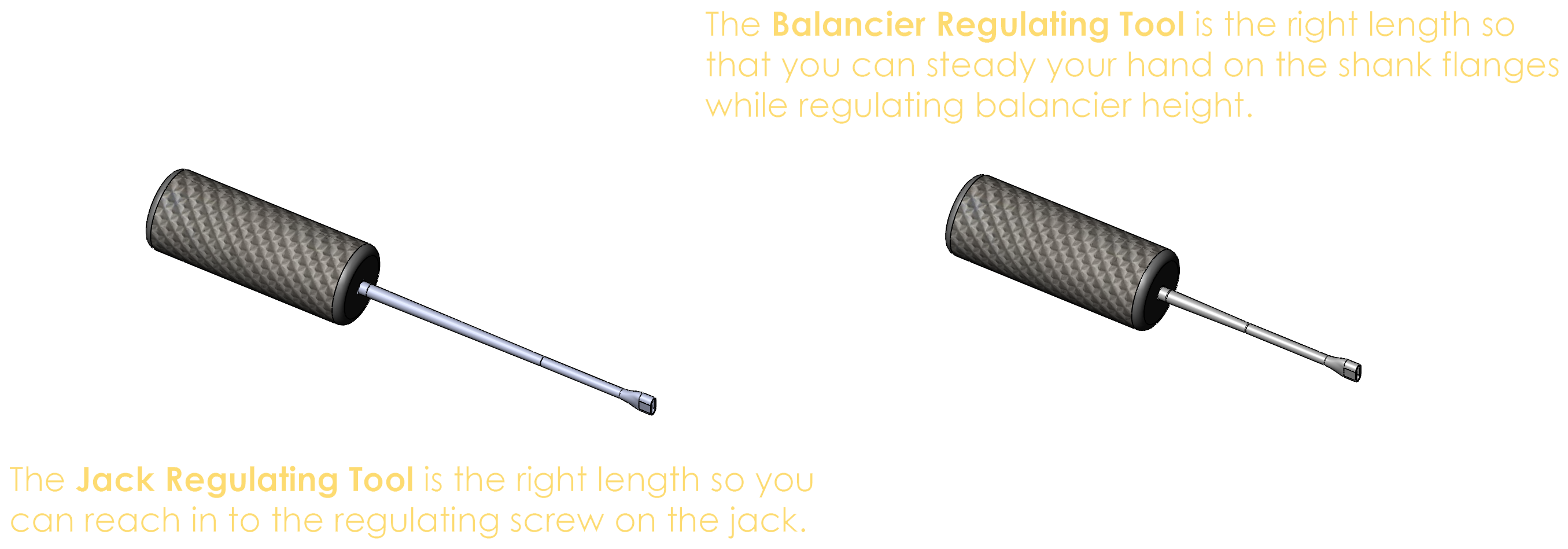

Balancier and Jack Regulating Tool

The handle and tool tip are the same on WNG's Jack and Balancier Regulating Tools--the only difference between the two are their lengths. The Jack Regulating Tool is the ideal length to reach in to the regulating screw on the jack.

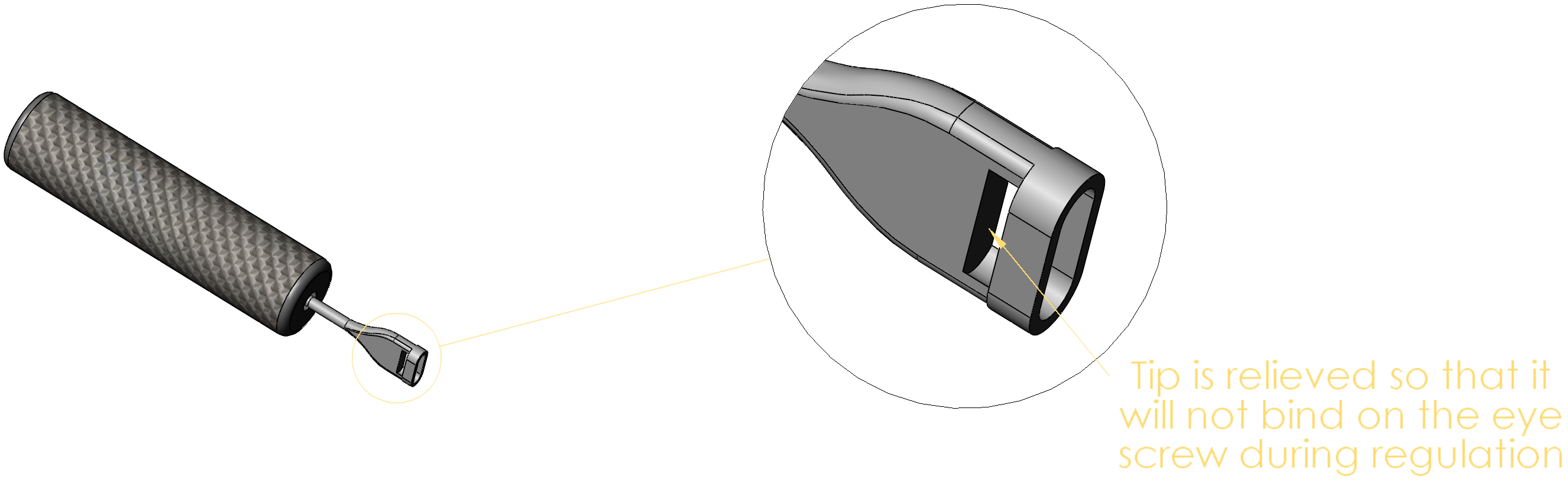

Let-Off

The WNG Let-Off Tool allows you to adjust let-off button eye screws during a bench regulation. The tool's length is ideal for steadying your hand on the shank flanges and its tip is relieved so that it will not bind on the regulating screw. *Please note that the WNG Let-Off Tool is designed for setting let-off on actions that use an eye screw. It is not the appropriate tool for dowel regulating buttons.*

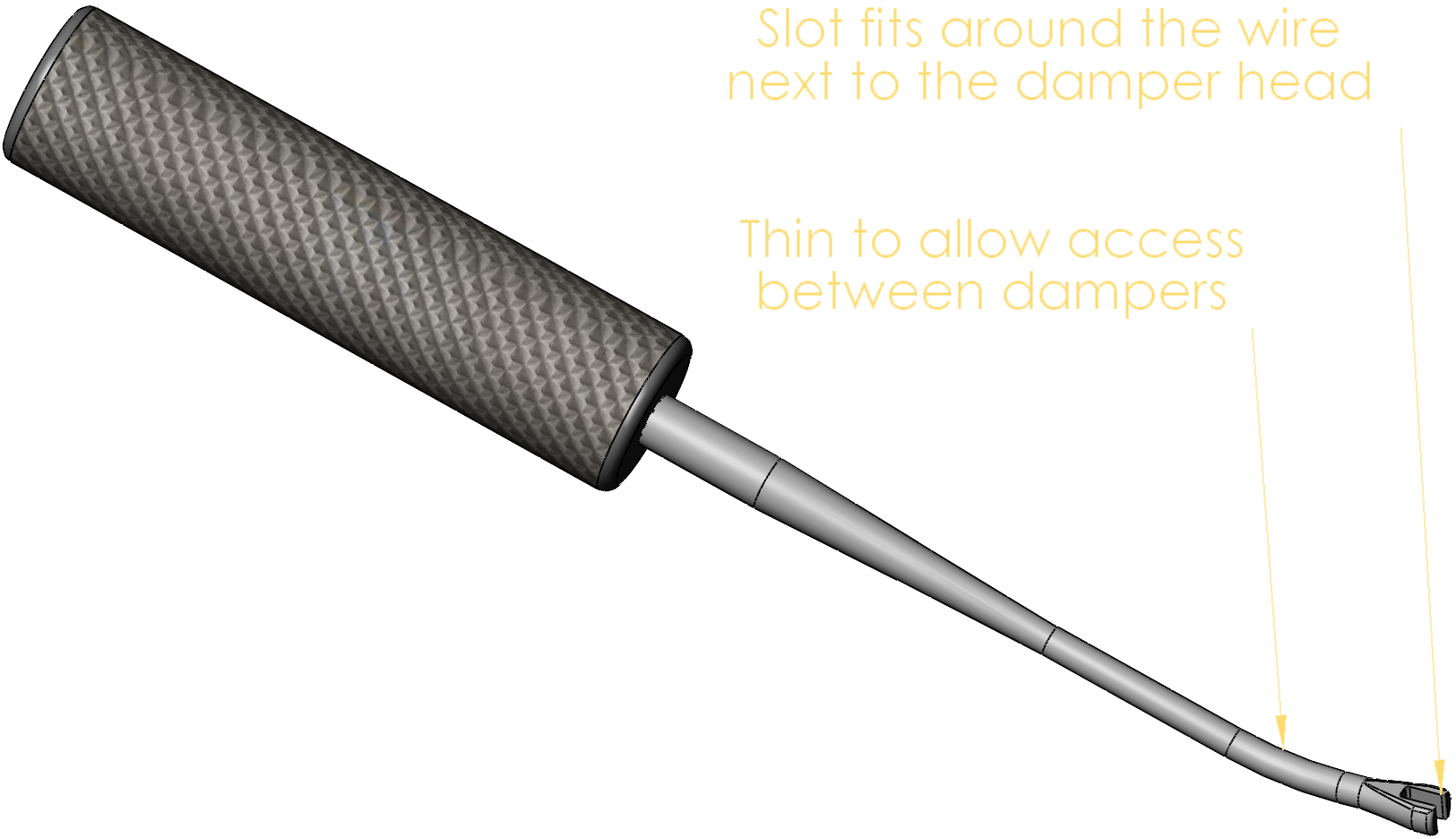

Damper Hook

Typically, piano technicians remove the damper to make the topbend--a process that is highly inefficient. When pianos are being manufactured, factory damper installer workers make this same bend while the damper is inside the piano, resulting is much less wasted time. WNG's Damper Hook enables piano technicians everywhere to use the factory's efficient method of making topbend while the damper is still inside the piano.

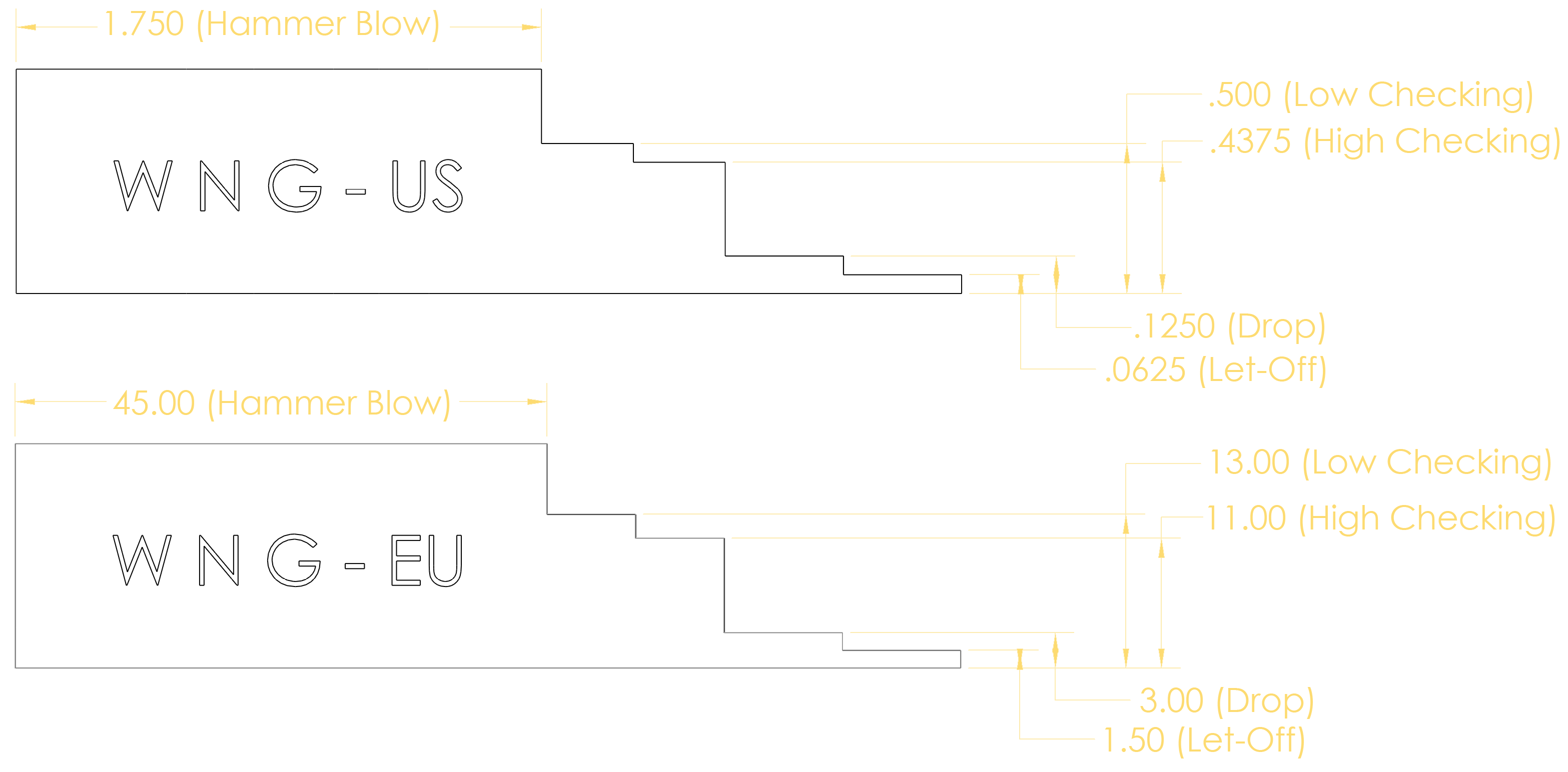

Dimension Gauges

WNG provides both metric and English gauges with the most common regulating dimensions used in bench regulations.

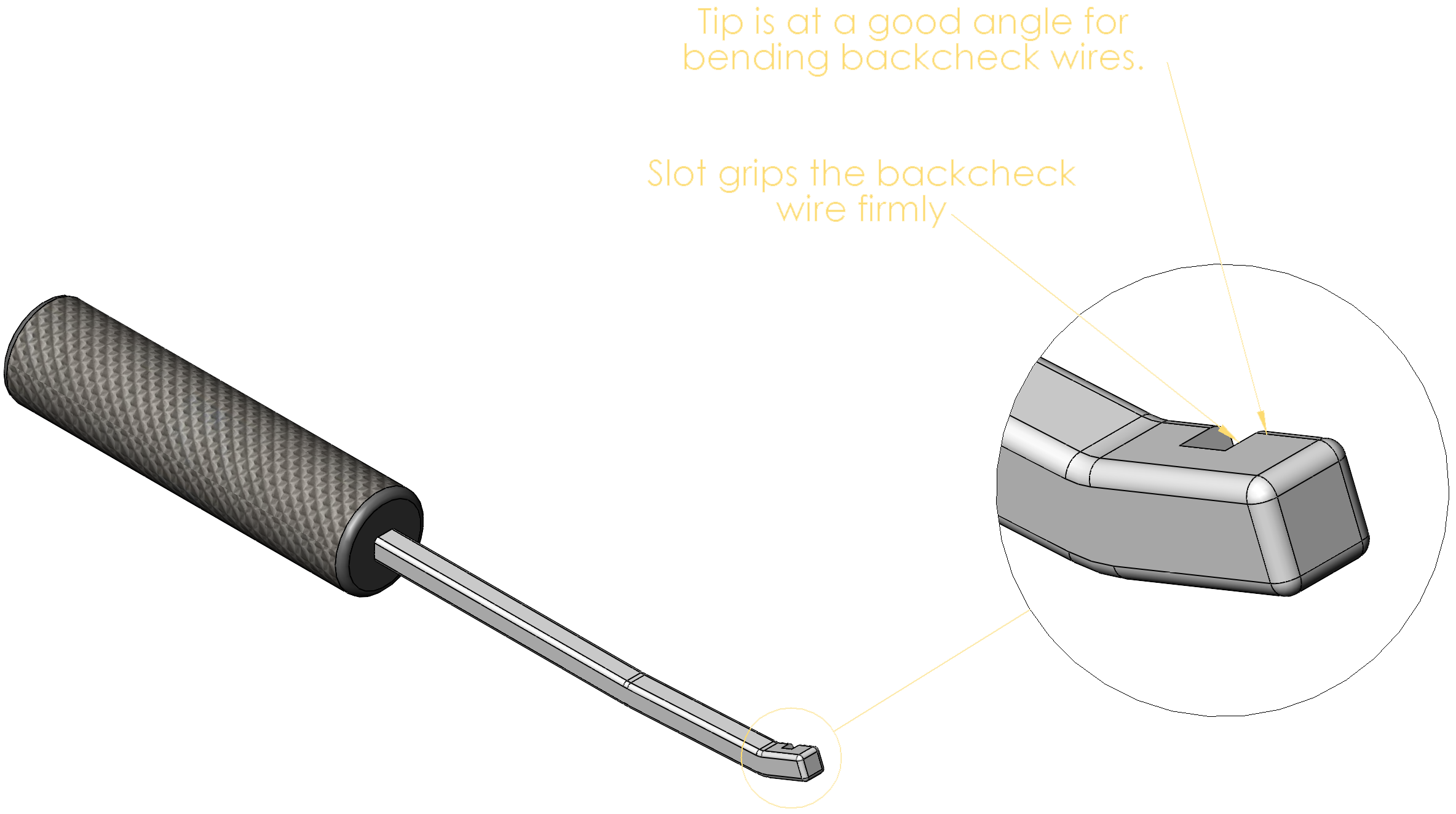

Backcheck Bender

The WNG Backcheck Bender was designed to be a comfortable yet functional tool with a slot to grip backcheck wire firmly and a tip with the ideal angle for bending backcheck wires. *Please note that this item is back ordered, call (573) 754-6690 for estimated ship date*

*Please note that this item is back ordered, call (573) 754-6690 for estimated ship date*

Part Number: 06-5670

WNG Pounder

Part Number: 06-5515