Capstans

Two things matter in a capstan, mass and a low coefficient of friction on its contact surface.

Most capstans are fashioned from brass. Unfortunately, brass is heavy and prone to tarnish. To combat this, the contacting surface is usually polished to reduce friction. This work-around is temporary, as tarnish will degrade the contacting surface making it somewhat sticky.

WNG's capstan is made from aluminum. Aluminum is light, about 1/3 the mass of brass.

After machining, we hard anodize the capstan. This coats the capstan with Aluminum Oxide, one of the hardest substances on earth. The hardness is as much as Rockwell C60 or about as hard as a planer knife. When polished, the capstan becomes very slick and durable.

What does a capstan do?

A capstan transfers the motion of the key to the repetition. Ideally, the capstan weighs as little as possible and has as low a coefficient of friction as possible on the surface that presses on the contact cloth of the repetition.

How is a typical capstan made?

The typical capstan is machined from brass usually in a screw machine.

Is there a problem with this?

There are two fundamental problems with a brass capstan.

Brass is heavy. This results in excessive mass. The mass of the capstan is then counterbalanced by more mass in the form of lead weights placed at the front of the key. The resulting inertia is felt by the pianist as more touch resistance than is really necessary.

Brass tarnishes. A smooth surface is polished into the brass as part of the manufacturing process. This makes the capstan have as low a coefficient of friction as possible. This is well and good for the first few days in the life of the piano. However, it doesn't take long before the brass capstan has a coating of tarnish that greatly increases the friction between the top of the capstan and the repetition contact cloth.

Is there a better Way?

The Wessell, Nickel & Gross aluminum capstan solves both of the problems of a brass capstan.

Aluminum is light. Aluminum is much lighter than brass. Depending on the variety of brass the specific gravity will be between 8.47 and 8.75. Aluminum has a specific gravity of 2.69, less than one third that of brass. Because of its weight, you don't see many airplanes manufactured from brass. With the availability of the WNG Aluminum Capstans you shouldn't see many brass capstans either. The use of aluminum reduces mass at an important place contributing to an action that plays well.

Anodized Aluminum does not tarnish. After machining and polishing, WNG runs the aluminum capstans through a process of hard anodization. This coats the capstan with a very hard surface (up to Rockwell 60) of aluminum oxide that will not corrode. When polished, this coating produces a stable and inherently slippery surface. Unlike brass, the WNG Aluminum Capstan will stay slippery indefinitely.

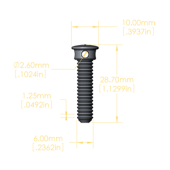

Capstan Set (Old Steinway)

Part Number: 06-5355

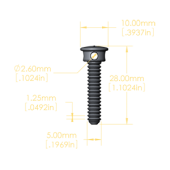

Capstan Set (Standard)

Part Number: 06-5303

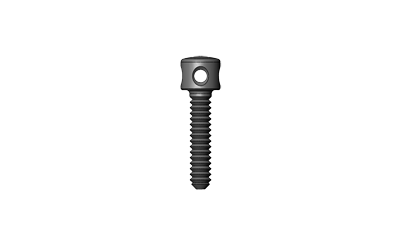

Capstan V1 Aluminum, Hard anodized, Set of 90

Part Number: 06-5330

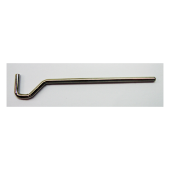

Capstan, Dowel for Vertical Pianos, Set of 90

Part Number: 06-0508

WNG Sample Parts Kit

Part Number: 06-5231