Backchecks

The WNG backcheck catches better than any other backcheck. This comes from the dense felt under the synthetic buckskin which creates a wedging, sliding stop. The WNG backcheck catches better than any other on a soft blow and will check at nearly the same place on a hard blow.

Multiple design innovations

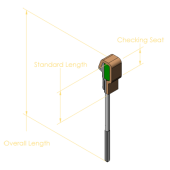

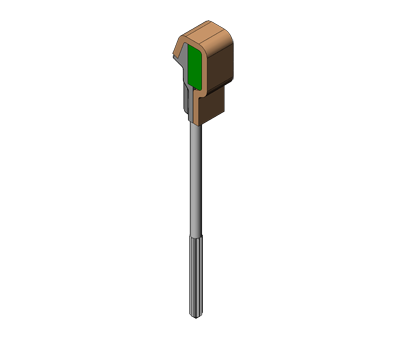

The backcheck body is made from WNG composite material and is much stronger than wood. A typical wooden backcheck is fat and bulky because wood is somewhat weak and the bulk is required for strength. By using the strength of composite material, WNG has designed a backcheck body that is shorter, thinner, lighter, and stronger than a typical wooden backcheck.

The WNG backcheck uses synthetic buckskin for a very good reason. After extensively testing backchecks and knuckles to the point of destruction, the test results were clear: synthetic buckskin outlasts natural buckskin by a substantial margin.

The WNG backcheck also uses a much denser felt under the buckskin. Traditional backchecks use a very soft felt under the buck skin and the consequence is that when the felt compresses, it becomes easier for the hammer to "slide through" or "bounce off".

Why is the WNG backcheck so short?

Most backchecks are much longer than necessary. Unfortunately, the extra length gets the customer nothing. A hammer is checked on the top 1/2" or so of the backcheck--checking a hammer any place else is simply incorrect. Below the seat, the only material required is to provide enough surface to glue the buckskin, so WNG has chosen to eliminate this unnecessary space.

Why is the WNG backcheck so thin?

Most rebuilders have experienced backchecks hitting the sostenuto after regulation. The reasons for this are varied, however, a thinner backcheck creates more room between the backcheck and the sostenuto, thus reducing the probability that the backcheck will hit the sostenuto when both are regulated properly.

These two features work together.

One downside of a longer wooden backcheck is that the extra length creates the area of the backcheck that would hit the sostenuto, resulting in a tapping sound. By shortening and thinning the design, WNG's backcheck eliminates this problem by simply having nothing there--it features air rather than wood in this location.

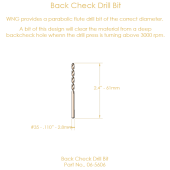

Careful Installation

All backchecks, WNG composite or wooden, must be installed correctly. If you use the system and tools provided by WNG to install these backchecks you should not encounter any problems.

Never use the hammer tail checkering file sold from a number of piano supply houses. The resulting roughness on the hammer tail will cause dramatically premature buckskin failure.

How To Install Backchecks

Learn how to install Wessel, Nickel & Gross backchecks, as well as how to tail the hammers. Backchecks wear out in a piano much like brake pads in an automobile. While wear is a valid reason to change the backchecks, ensuring accurate and consistent checking is even more important.

Watch the video to the right, then download the full installation manual below. You can also download a high-resolution version of the video that you can watch offline, or burn to DVD. To save any of these files to your computer, right-click on them, and then select the "Save Target As" (or equivalent) option.

Standard Backchecks (for angled holes)

Part Number: 06-5201

Standard Backchecks (for vertical holes)

Part Number: 06-5200

WNG Sample Parts Kit

Part Number: 06-5231