Understanding Composite Shanks

Why are composite shanks better? In a word: consistency. Shanks are a critical component in the transfer of energy from the fingertips of a player to the strings on a piano.

Wooden shanks vary widely, resulting in inconsistent characteristics across the keyboard. Some individual hornbeam shanks are perfect, while others have variations that result in poorly distributed mass, compromised strength, or too much flex.

Composite shanks have the characteristics of the best wooden shanks, and can be manufactured consistently. For the technician, composite shanks remove a challenging variable from the regulation. Artistically, it gives a player predictable expression and better control of the instrument.

Detailed Analysis

Wessell, Nickel & Gross (WNG) composite piano hammer shanks are designed to give the pianist more power and control. The result of our efforts is a wider dynamic range, with the added benefit of improved tonal response and a lighter touch.

Two closely related parameters guiding this development were mass and strength. Given the construction of piano hammer shanks, mass and strength are inextricably linked. In terms of piano action performance, mass should correlate with strength in a uniform way.

Several factors conspire to violate that ideal. The largest offender is the most common material used to construct piano parts: wood. For many components of the piano, there is currently no other cost-effective or suitable option than wood. However, hammer shanks are one of the most obvious places where improvement can be realized, and where a piano's potential can be maximized.

The principle shortcoming of a wooden hammer shank is in its non-uniformity. Graphs of data gathered during development show how Wessell, Nickel & Gross has succeeded in creating a shank capable of delivering both power and control. A perusal of this data will give insight into the areas of piano performance benefiting from use of this technology. Though of course, there is no better way to discern this improvement in shank design than by playing a piano equipped with them!

Mass

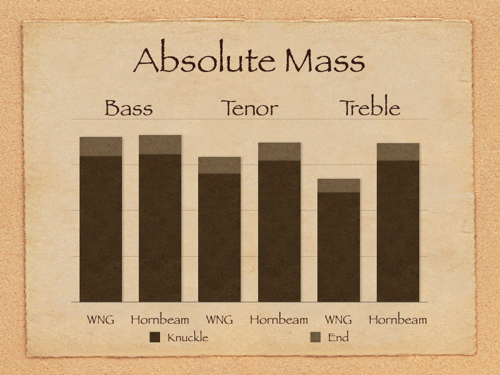

Due to the construction of WNG shanks, the overall mass is greater than for hornbeam shanks, but the center of gravity is shifted closer to the action center compared with their wooden counterparts. As can be seen in the "Absolute Mass" graph, this shift is reflected in the lower mass compared to hornbeam shanks seen at the knuckle and at the shank end, the two places where it is most relevant.

For the knuckle measurement, the shank was supported at the action center, while gravitational mass was measured at the center of the knuckle area. Lower mass at the knuckle (as well as the shank end) means less lead needs to be added to the keys--allowing a lighter and more responsive action to be constructed.

Many technicians remove material (mass) from hammers to achieve more sustain and to impart more of a "singing" quality to their pianos. Typically, this is done from approximately the middle of the piano range and into the treble section.

The mass of WNG composite shanks at the shank end is somewhat less than hornbeam in the tenor and treble shanks, where it is more desirable to have less mass. This assists the technician in achieving a better quality of tone through the middle and upper registers of the piano. Lower mass at the end of the shank also translates to a faster rebound from the string and a quicker action able to repeat faster.

Although WNG composite tenor shanks possess more than adequate strength for use in the bass section, our composite bass shanks have been designed to be comparable to hornbeam in mass at the shank end. This is desirable to ensure sufficient energy is delivered to the much more massive bass strings for a reasonable amount of exertion or key acceleration.

Mass Variability

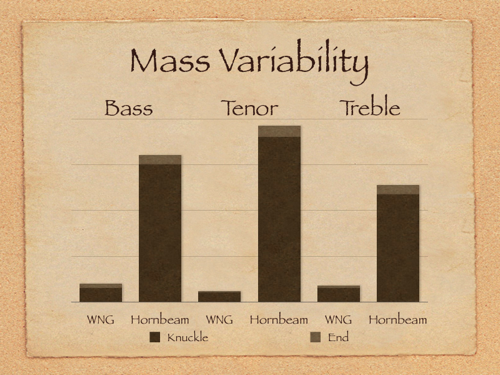

One of the most compelling aspects of WNG composite shanks is their greater uniformity over wooden shanks in mass and strength.

The "Mass Variability" graph dramatically illustrates the more tightly controlled mass of composite material, when compared to hornbeam. For example, the variability of mass at the knuckle in tenor hornbeam shanks is 1700% greater than for WNG composite tenor shanks. At the shank end, a hornbeam tenor shank is 900% more variable in mass than a WNG composite tenor shank.

This means that two adjacent WNG composite tenor shanks may vary in mass at the knuckle by no more than 0.40grams, and at the shank end by no more than 0.05 grams. Alternately, the mass of two adjacent hornbeam shanks can vary by as much as 7.20 grams at the knuckle and 0.5 grams at the shank end. This disparity in hornbeam shanks must be compensated for during initial weighting of the keyboard, and ultimately in the final voicing.

With WNG composite shanks there is a greater likelihood that inertia in the system, meaning all the moving parts from the key to the hammer, will graduate more consistently from note to note. This translates into a more even touch response felt in the fingers. Pianists can concentrate more on expression and phrasing, and not be distracted by inconsistencies in some keys compared to their neighbors.

Strength

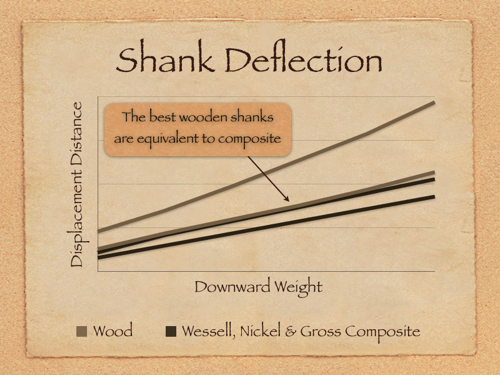

To compare the strength of WNG composite and hornbeam shanks, both were stressed in an identical manner. Static forces of 1 to 6 pounds were applied to the ends of the shanks. In the “Shank Deflection” graph it is clear that hornbeam shanks deflect more for a given amount of force applied than composite shanks.

As increasing force is applied to both, hornbeam consistently loses to composite. An instrument equipped with composite shanks will have a wider dynamic range than it would with hornbeam shanks. That's because more of a pianists' force will propel the shank (and thus the hammer) toward the string rather than flexing it.

Some of the mechanical energy stored by bending a shank is recovered as the shank returns to its straight orientation. However, some energy gets lost when forces from the upward bending area near the knuckle move back down--canceling some of the upward force at the hammer shank end. None of the energy lost as heat from internal friction in a hornbeam shank’s bending can be recovered as useful force. Composite shanks are much stiffer than hornbeam, so more energy is delivered to the string.

Strength Uniformity

As can be seen in the "Shank Deflection" graph, the range of deflection values is much wider in hornbeam shanks than in WNG composite shanks. All the benefits of greater uniformity in mass also apply to strength, which is reflected in deflection measurements. Again, the greater uniformity in strength of composite shanks is one of their most compelling aspects.

Unfortunately, any combination of strength properties is possible in two adjacent hornbeam shanks of the same type (bass, tenor or treble) since placement of shanks in an action is typically left to chance. They are not sorted for mass or for strength. Even sorting for mass would not eliminate strength disparities in hornbeam shanks. In hornbeam shanks, mass does not correlate with strength very well so a heavier weaker shank may sit next to a lighter, stronger shank.

Even more disconcerting with the use of hornbeam shanks is that it is possible to have a bass shank with less strength than a tenor shank or even a treble shank. These situations only exacerbate work required by the technician in voicing--and finally the pianist--to keep things under control.

Two adjacent hornbeam hammer shanks may vary in mass and strength enough to noticeably impact their relative touch weight and inertia. The variability also affects energy delivered to the string, effort required by the player to deliver consistent force, the time a hammer stays in contact with the string, the ability of a hammer to excite vibrations on the string, even absorption of harmonic frequencies, and the rebound rate.

The tighter uniformity of WNG composite shanks greatly reduces the variance from shank-to-shank, eliminating the problems described for hornbeam shanks. A player’s pianissimos will benefit from the greater uniformity, and thunderous fortissimos are more predictably unleashed. There is simply no substitute for a stronger and more uniform hammer shank.

Emergence

Wessell, Nickel & Gross has satisfied the need for hammer shanks that silently contribute to the voice of a piano, allowing a pianist to focus more on what matters most--the sound.

WNG composite shanks are only a part of the whole picture, and will work in concert with additional groundbreaking WNG components such as low-friction aluminum capstans, reduced mass/improved geometry backchecks, composite under-levers, low-friction key pins, and in particular, uniform composite repetitions. With all of these components working together, what emerges is a system that allows the technician and the player to get the most out of their instruments. Wessell, Nickel & Gross is more than the sum of its parts!