Shanks and Flanges

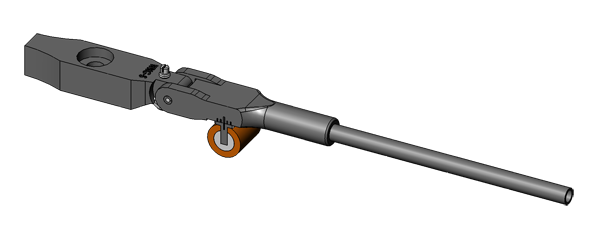

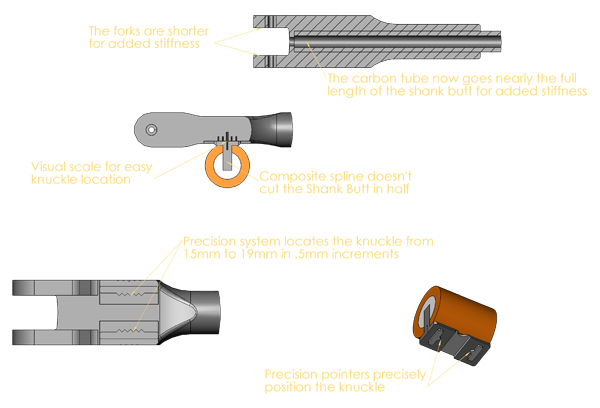

The WNG Composite Hammer Shank combines a composite Shank Butt and a Carbon Tube Shank. The Shank Butt is made from the standard WNG black composite and the Carbon Tube Shank is a pultrusion made from Carbon Fiber and Epoxy. The resulting part is extraordinarily stiff and does not suffer from the tendency of a wooden shank to bend and whip

More Information:

The video on the right was filmed using a high-speed camera and shows what happens when a wooden shank and a WNG Carbon Tube Shank are played. It explains that because wood is an organic material, its quality is very inconsistent and out of an entire set of shanks, only a few are truly "strong", yet every shank is used.

A WNG Carbon Tube Shank's strength is as strong as the strongest wooden shank, but doesn't have the variability in quality that wood does. You can be sure that every WNG Carbon Tube Shank is as strong as the one next to it, and that any piano action equipped with WNG's Carbon Tube Shanks will see a notable increase in power, consistency, and longevity.

- Understanding Composite Shanks

- Download the Composite vs. Wooden Shanks High-Resolution Video.

- Download the How To Install Composite Shanks and Flanges Video.

WNG sells hammers!

Click here to visit our hammer page!

Need a drill bit?Click here to visit our drill bit page!

The Completely Redesigned WNG Hammer Shank

What is "whipping"?

A hammer shank has a rough life. When a pianist plays a key, the hammer is required to accelerate at roughly 5 times the rate of the key. A wooden shank lacks the strength required to accelerate the hammer this rapidly and thus bends backwards for a short period of time. The shank then becomes a spring capturing some of the energy of the blow. A few milliseconds later, the shank then whips forward. It does not, however, recover all of the captured energy.

Does a shank really need to whip?

No! For years whipping was thought necessary for the simple reason that all wooden hammer shanks exhibited this behavior.

When a wooden hammer shank bends under its load, some of the energy that should actuate its strings is lost, dissipating into the fibers of the wooden shank as heat. Because of this, a wooden hammer shank is very inefficient.

To eliminate this problem, WNG uses a carbon shank which is very stiff and minimizes bending. Substantially less energy is lost to bending, thus the WNG carbon shank is much more efficient. This translates into much more powerful sound when a note is played.

Three Levels of Strength

Wessell, Nickel & Gross’ carbon fiber shanks come in three strengths: Flex 1, Flex 2, and Flex 3. The strength of each Flex is based on information taken from 40 different sets of wooden shanks.

- Flex 1 shanks are as strong as the strongest wooden shank

- Flex 2 shanks are as strong as the strongest Renner shank

- Flex 3 shanks are as strong as the average of all 40 sets of wooden shanks

Each shank in every Flex has an outer diameter of 4.67mm and a wall thickness of .80mm. The same drill bit can be used for all three shank Flexes.

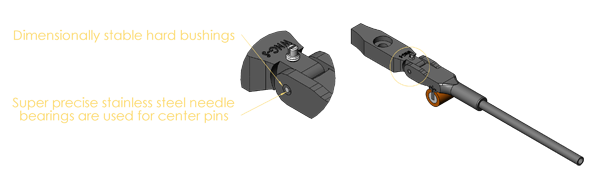

Hard Bushings

Cloth bushings have problems:

- - Cloth bushings are unstable in a changing humidity environment

- - As cloth bushings change, center pin torque changes

- - As pin torque changes so does the touch of the piano

In comparison, hard bushings are quite advantageous:

- - Hard bushings are dimensionally stable as humidity changes

- - When exposed to changing humidity, pin torque change is negligible

- - The change in the touch of a piano is negligible

Test Results: After 18 million blows, pin torque exhibited virtually no change. In extreme environments, from 10% to 90% Equilibrium Moisture Content, pin torque was stable.

Read how Wessell, Nickel & Gross succeeds where Teflon bushings failed...Dimensionally Accurate Flanges

WNG has carefully engineered flanges for popular models so that the flanges provide a correct fit to the existing rails.

Organized into sets for popular models of pianos

WNG has organized sets of shanks and flanges for a number of popular pianos. Each set includes the appropriate flange, knuckle location and knuckle diameter. All sets feature three tube graduations for power and sustain.

Select one of our pre-configured models, or configure your own custom shank and flange.

Custom Shank & Flange Set

Part Number: 06-5106-10

Custom Shank & Flange Set, (knuckles not attached)

- Understanding Composite Shanks

- Download the How To Install Composite Shanks and Flanges PDF Manual.

- Download the How To Install Composite Shanks and Flanges Video.

Part Number: 06-5106-11

Custom Shank & Flange Set, Flex2

Part Number: 06-5106-20

Custom Shank & Flange Set, Flex2 (knuckles not attached)

Part Number: 06-5106-21